In manufacturing engineering, a variety of design file formats are available, making it crucial to choose the right one for 3D printing and other manufacturing processes. Selecting the appropriate format ensures smooth workflow and accurate results. Different formats, such as STL, STP, OBJ, and IGS, serve specific functions. Some are perfect for 3D printing, while others are better suited for CAD design or CNC machining. Understanding these file types simplifies the design-to-production process while ensuring compatibility and correctness. In this guide, we'll look at the distinctions between STL, STP, OBJ, and IGS files and help you decide which one is ideal for your individual project requirements.

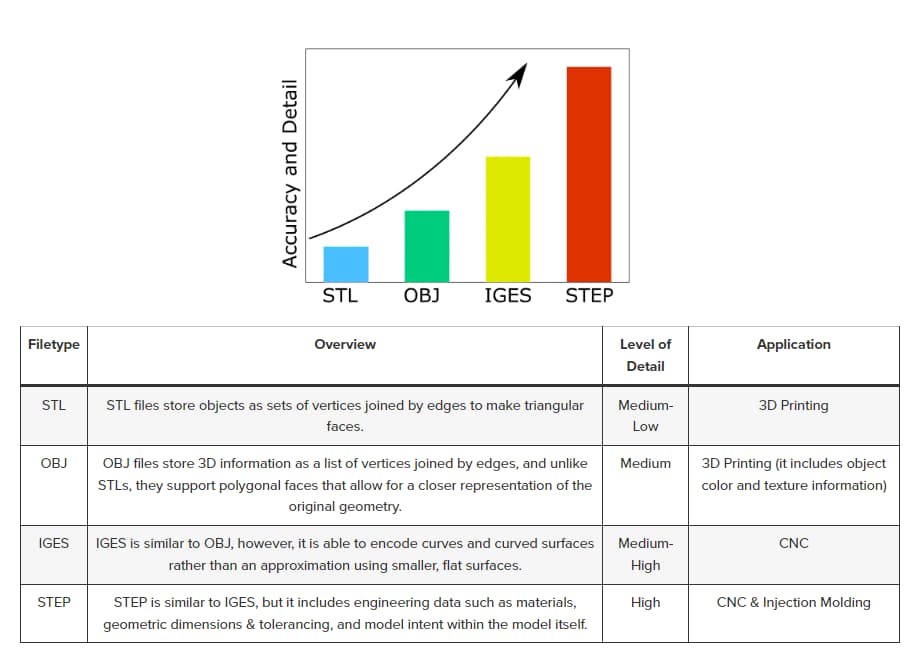

Accuracy and details in different 3D files

Different 3D file formats provide varying degrees of accuracy and detail. STL files are popular in 3D printing due to their simplicity, focusing on fundamental geometric shapes, although they lack delicate details such as texture and color. STP files (STP) are more precise, capturing detailed 3D geometry, including material and assembly information, making them excellent for CNC machining and complex designs. OBJ files give more visual information by storing not only geometry but also textures and colors, making them popular in visual design. IGS files provide precision in surface modeling and are commonly used in CAD applications, ensuring efficient data sharing in engineering workflows.

STL

The STL file format (Stereolithography) is one of the most popular file types for 3D printing. STL files contain a 3D object's surface geometry as a triangle mesh, making them ideal for 3D printing. However, STL files do not include color, material, or texture information, making them less suitable for sophisticated design tasks. When working on a 3D printing project that requires precision, an STL file is typically the preferred format. Most 3D printers and CAD software support STL, making it the industry standard.

STP

STP files, also known as STEP (Standard for the Exchange of Product Model Data), are widely used in CAD for manufacturing. Unlike STL files, STP files contain detailed 3D model information, such as geometry, texturing, and assembly hierarchy. This makes STP the preferable format for CNC machining, sheet metal fabrication, and other traditional manufacturing methods. If you deal with parametric design or require a file format for engineering purposes, STP is an adaptable and strong solution. STP files are interoperable with the majority of CAD systems, allowing for seamless data exchange across platforms.

IGS

IGS files (Initial Graphics Exchange Specification) are commonly used in CAD applications to represent 3D models in a uniform format. IGS files, like STP files, hold both geometric data and detailed features such as curves and surfaces, making them suitable for CNC machining and injection molding. IGS files are especially beneficial for transferring 3D models across different CAD platforms, ensuring that no critical data is lost in the process. While IGS is not as widely used for 3D printing, it remains an important format in traditional manufacturing procedures that demand great precision.

OBJ

The OBJ is widely used in 3D modeling and printing, owing to its ability to include not only geometric data but also material information like colors and textures. This makes OBJ perfect for tasks requiring high levels of visual detail. OBJ files work with a variety of 3D modeling tools and are widely used in industries such as gaming, animation, and product design. However, for 3D printing, OBJ may not always be the most efficient file type, unless textures and colors are necessary. Converting from STL to OBJ might be advantageous when additional visual detail is required in the final output.

Other Formats for 3D Printing

Aside from STL, STP, OBJ, and IGS, 3D printing and CAD use a variety of different file formats. AMF (Additive Manufacturing File) is intended for 3D printing and may include more detailed elements such as color, materials, and lattice structures. 3MF (3D Manufacturing Format) is a newer file format that addresses the constraints of STL by providing higher quality and support for complicated structures. Another format, PLY (Polygon File Format), is frequently used to store scanned 3D data. Understanding these other file types will provide you more options when working with complex 3D models and production procedures.

Why Choose the Right Format for Manufacturing?

Choosing the appropriate file format is critical in manufacturing since it has a direct impact on the accuracy and quality of the finished product. For example, STL files are ideal for 3D printing, whereas STP and IGS files excel in CNC machining and injection molding due to their detailed geometric data. Choosing the incorrect file format might lead to compatibility issues, poor print quality, or inaccurate models, thus it's critical to match the file type to the project specifications.

STL/OBJ for 3D Printing

In 3D printing, both STL and OBJ files are commonly utilized. STL files are ideal for quick, no-fuss 3D printing projects when detail is not critical, but OBJ files provide greater versatility by allowing color and texture data to be retained. STL vs. OBJ: STL is more simple, whereas OBJ is better for visually complex objects. For 3D printers that allow full-color printing, OBJ may be a better option, but STL remains the industry standard due to its widespread compatibility.

STP/IGS for Traditional Manufacturing

Both STP and IGS file formats perform well with traditional manufacturing methods such as CNC machining, injection molding, and sheet metal work. STP files provide more depth in terms of 3D geometry, assembly, and product data, making them ideal for mechanical designs and engineering projects. IGS files are very commonly used, particularly for moving drawings across CAD programs. If precision is important in your manufacturing process, using one of these formats helps ensure a smooth transition from design to production.

STL vs. OBJ: Understanding the Differences

While both STL and OBJ formats are utilized in 3D printing, they serve distinct functions. STL files are simpler and focus solely on the geometry of a 3D object, making them suitable for rapid prototyping. OBJ files, on the other hand, may include additional data such as textures and colors, making them handy for more complicated projects. The choice between STL and OBJ is mostly determined by the project's complexity—STL for simplicity and OBJ for sophisticated, color-specific applications.

Convert STL to OBJ

If you need to add more visual information to an existing 3D model, converting from STL to OBJ is a standard method. This conversion allows you to add color and texture information to an STL-based model, which is particularly valuable for 3D visualization or product design applications. Many CAD software programs include built-in converters, which make it simple to switch between these file types based on your requirements.

STP vs. OBJ: Choosing the Right Format for CAD

When it comes to CAD design, the complexity of the project determines whether to use STP or OBJ files. STP files are appropriate for engineering applications that require detailed geometry and assembly information. In contrast, OBJ files are better suitable for visual activities like rendering or 3D modeling for animations or games. While most CAD software supports both formats, STP files are more useful for production, while OBJ files are better suited for design visualization.

Why 3D Printed Models Have To Be in STL and STP File Formats? (Word count: 120)

Because of the unique requirements of 3D printing and manufacturing, 3D printed models are often saved in STL or STP formats. STL files are ideal for 3D printing because they contain a simplified, mesh-based representation of the thing that 3D printers can understand. STP files, on the other hand, are required for projects that use CNC machining or other traditional production methods since they contain more complicated geometric data. The choice between STL and STP is mostly dependent on the production procedure, however both formats assure that the model is manufactured precisely.

Manufacturing with LUSHI ENGINEERING

LUSHI ENGINEERING specializes in transforming your 3D drawings into high-quality, manufacturing-ready products. Whether you're dealing with STL files for 3D printing or STP/IGS files for tooling and CNC machining, our expert staff will ensure that your designs are created accurately and precisely. We handle several file types, allowing for seamless integration from design to final result. Simply upload your files to get instant and free quote from our experts.