Two-shot injection molding is a type of manufacturing process where two materials are "overmolded" in one cycle. As the name implies, only two different materials or different colors are injected into the molding machine to mold the plastic parts. However, some precise injection molding machines are needed to implement this process effectively.

Two-Shot Injection Process

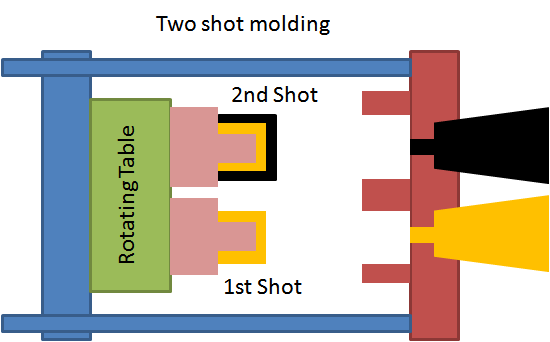

Step-1 : Inject the molten plastic into injection mold tool using the first barrel. And then make the mold core and cavity Separation.

Step-2 : Rotate the molding tool to bring in position of second barrel.

Step-3 : Close the molding tool and inject the molten plastic into the mold using the second barrel. After the cooling of material, the molded part pops out of the injection mold.

Two-shot molding for plastic manufacturing requires that a first polymeric part is injected into the molding cavity, and it is done with processing; the second part is inserted, which is used to complete the molding process. For an effective two-shot molding process, the two materials to be used must be chemically complementary (that means they must have similar chemical properties).

Two-shot injection molding could be implemented in manufacturing mass production of plastic parts as a medium to bond the hard part of the plastic with another soft material. The process consolidates the molding of two components in a two-cavity mold. It can significantly enhance the appeal of the product in terms of color, texture, and so much more. Two-shot molding provides a wide range of design opportunities. Also, for manufacturing plastic, it could be best implemented in the production of switches, buttons, handles, and container caps.

By using the two-shot molding process, two parts could be mixed to produce a single, more efficient piece through one molding method instead of the regular two. An engineer or industrial designer will design the desired plastic part, and then a toolmaker will craft the mold that is needed to produce the components that are required. Precision machining is used to make the mold, with the frame composed of either steel or aluminum.

Advantages of Two Shot Injection molding Technology

There are a variety of reasons why most manufacturers prefer using the two-shot injection molding technology for manufacturing plastic, and one of the reasons could also be that it uses only one production cycle. This process is cost-effective because it uses only a single production cycle instead of two, which requires a smaller workforce to achieve a standard end product while producing multiple items per cycle.

However, it also ensures strong bonding between the plastic materials without the need for further assembly down the line and enhances product quality. Below are various ways two-shot injection molding enhances the quality of most thermoplastic materials:

• It offers a better seal when silicone plastics and other rubbery materials are used for gaskets and other parts that require a secure seal.

• It allows for the combination of both hard and soft polymers for exceptional comfort and utility for even the least of products.

• Improved esthetics Items look better and are more appealing to the consumer when they are crafted of different colored plastics or polymers. The merchandise seems more classy and expensive if it has more than one color or texture.

• Improved ergonomics Because the process allows for the use of soft-touch surfaces, the resulting items can have ergonomically designed handles or other parts. This is particularly important for tools, medical devices, and other hand-held items.

• It can significantly reduce the number of misalignments when compared to over-molding or more conventional insert processes.

• It enables manufacturers to create more complex mold designs using multiple materials that cannot be efficiently bonded using other methods.

• The bond created is solid, creating a product that lasts longer and is more reliable.

More efficiency with the two-shot molding

Plastic product manufacturers prefer two-shot injection molding for a wide range of applications, including medical devices, automotive interior parts, mobile gadget parts, and toys. It allows for the combination of a variety of materials and colors to produce a final product that is both potent and attractive. Some materials that can be effectively combined with this process include nylon, silicone, thermoplastics, thermoplastic elastomers, hard plastic, and soft-touch materials.

The two-shot molding requires a single production cycle, which not only reduces the labor required but also saves the whole production time, reducing the production cost greatly. With the development of injection molding technology, more and more plastic products with multi-shots will be brought into the market in the future.